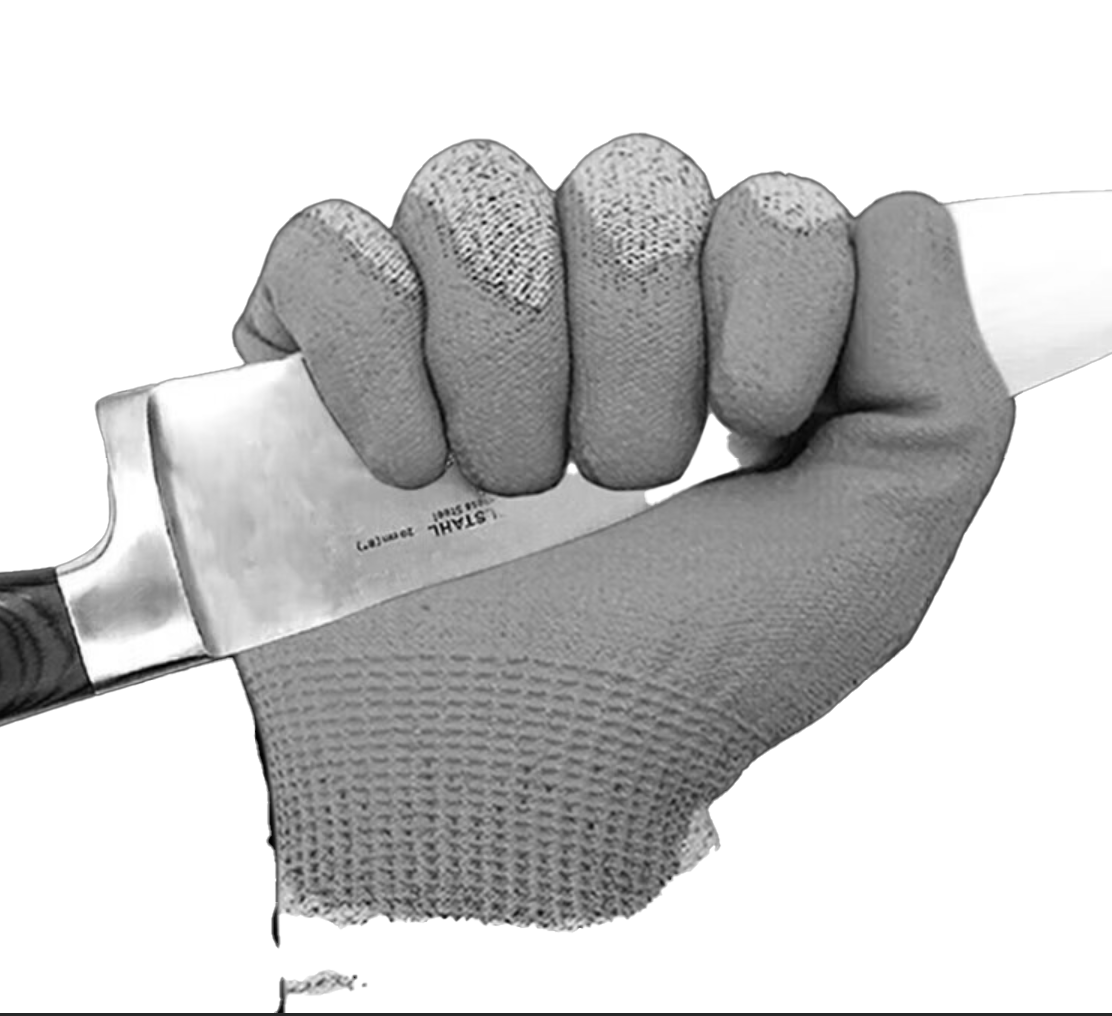

Cut resistant work gloves

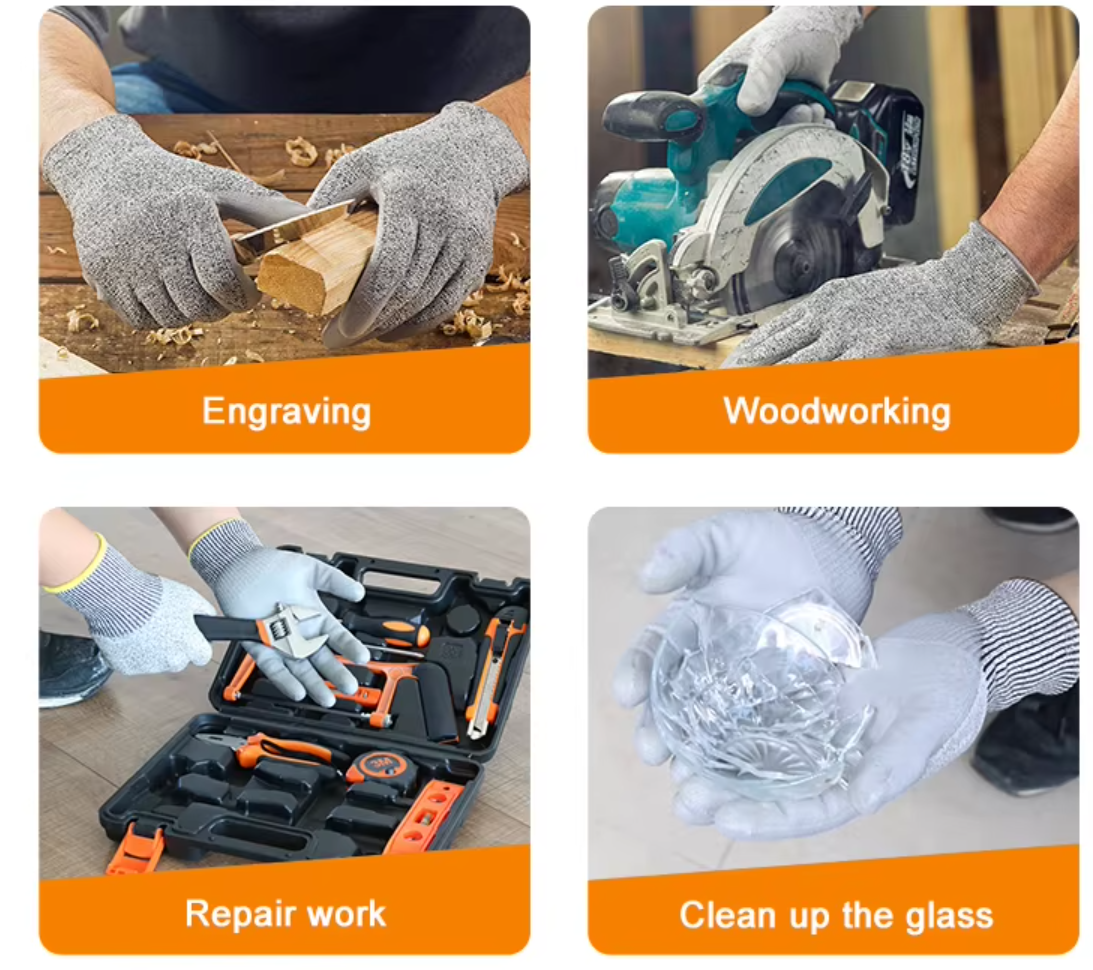

* Garden work,Manufacturing, Automotive repairing, Restoration etc

Anti-cutting gloves is a kind of protective gloves specially designed to prevent hands from being cut by sharp objects

(such as knives, metal edges, glass, etc.), widely used in food processing, metal manufacturing, construction, rescue and other fields.

The following is a detailed analysis of cut-resistant gloves, including their definition, protection levels, and the necessity of use:

1, what is cut-resistant gloves?

1. Material and structure

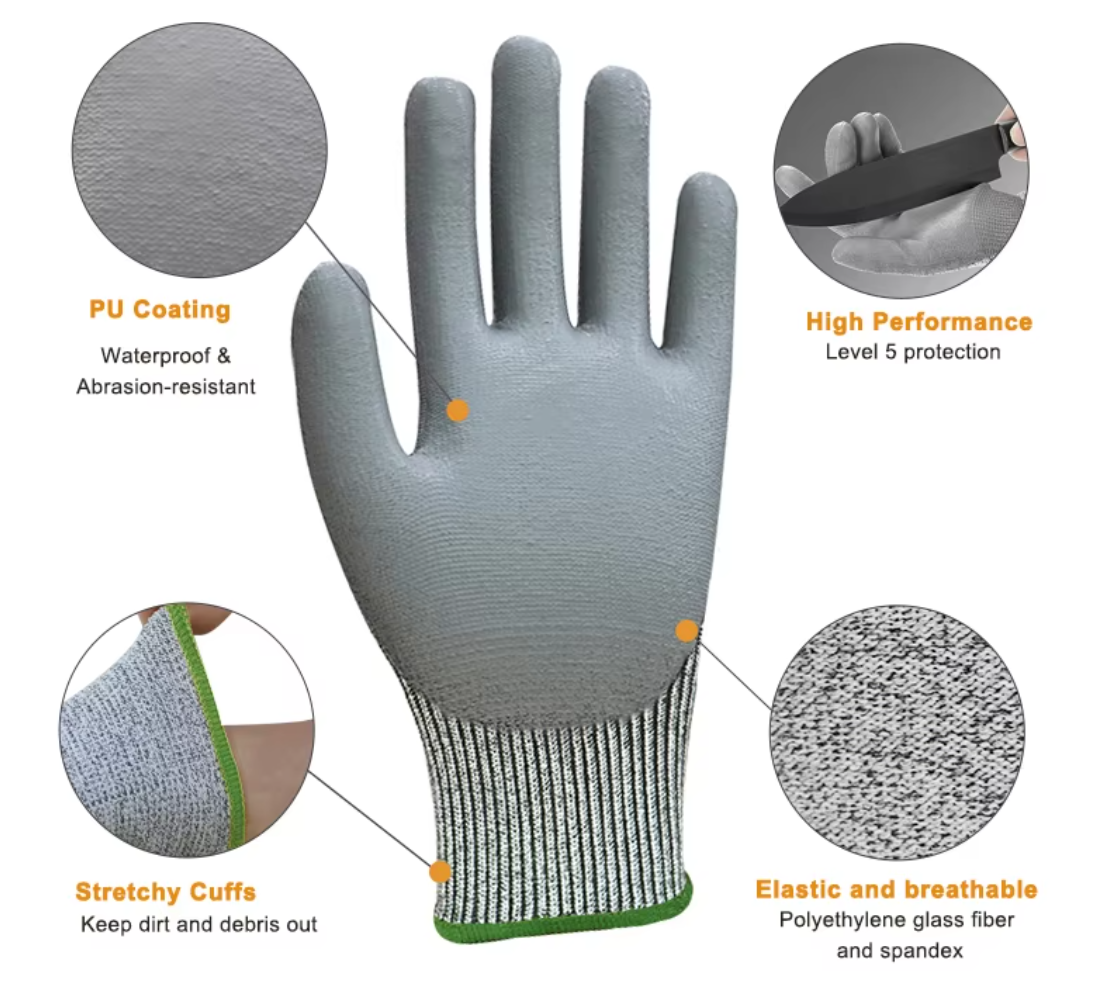

- Core material : Made of high strength fibers (such as HPPE, Kevlar, stainless steel wire braided) or composite materials.

- Process design : By knitting, weaving or coating process, the formation of dense mesh structure, effectively prevent sharp objects from directly touching the skin.

- Surface treatment : Some gloves are coated with PU or anti-slip particles to enhance grip strength and wear resistance.

2, functions

- Anti-cutting : Disperse the cutting impact force through the toughness of the material, reduce the risk of being cut by the tool and sharp instrument.

- Anti-puncture (some models) : Resist puncture by sharp objects such as needle tips and metal debris.

- Flexibility : Balance protection and freedom of hand movement, suitable for fine operation.

2. Protection level of anti-cutting gloves (taking EN 388 standard as an example)

The international **EN 388 standard ** grades the protective performance of gloves against mechanical damage, of which the Cut Resistance Level is expressed by the Cut resistance level (Cut Resistance Level) **, the higher the grade, the stronger the cutting resistance:

| ** Grade ** | ** Cutting test result (index) ** | ** Typical application Scenarios ** | ** Examples of materials ** |

|----------|--------------------------|--------------------------------------|----------------------------------|

| **A** | 1.2 ≤ index < 2.5 | Minor risks: paper, plastic edges, lightweight packaging | Common fiber gloves (cotton/polyester) |

| **B** | 2.5 ≤ index < 5.0 | Moderate risk: food processing, glass handling | nylon blend gloves |

| **C** | 5.0 ≤ index < 10.0 | Higher risk: sheet metal processing, wood cutting | Kevlar gloves |

| **D** | 10.0 ≤ index < 20.0 | High risk: slaughterhouse, assembly of metal parts | Stainless steel wire composite fibre gloves |

| **E** | ≥ 20.0 | Very high risk: rescue broken, heavy machinery operation | High density polyethylene (Spectra) gloves |

Other relevant protection grades ** (supplement to EN 388 standard) :

- Anti-puncture grade (P) : Level 1~4 (Level 4 is the highest), the test object is the standard nail tip.

- Wear-resistant grade (A) : Grade 1~4 (Grade 4 is the highest), the number of wear-resistant test materials.

- Tear Resistance Rating (T) : 1~4 (4 highest).

3, why use cut-resistant gloves?

1. Prevention of occupational injuries

- ** Reduces cutting accident rate ** : In the meat processing, glass manufacturing, metal processing and other industries, hand cuts are common injuries, cutting gloves can significantly reduce the depth and frequency of wounds.

- ** Avoid the risk of infection ** : Sharp cuts can cause infections such as tetanus, and protective gloves provide a physical barrier.

2. Improve work efficiency

- ** Flexible Handling ** : Lightweight high-grade gloves, such as Spectra fibers, allow the wearer to use the tool flexibly, reducing handling errors caused by heavy gloves.

- ** Non-slip design ** : Surface coating or texture enhances grip and prevents tools from slipping.

3. Comply with regulations and safety standards

- ** Industry mandatory requirements ** : such as food processing (HACCP), construction industry (OSHA), etc., require employees to wear cut-resistant gloves in specific scenarios.

- ** Corporate Responsibility ** : Providing compliance protective equipment can reduce corporate legal risks and protect employees' rights and interests.

4. Economy

- ** Reduced medical expenses ** : Preventing cuts reduces the cost of injury treatment and missed work.

- ** Extended glove life ** : High-grade gloves have strong durability and long-term use costs are lower than frequent replacement of low-end gloves.

4, how to choose the right anti-cut gloves?

1. ** Match protection requirements according to risk level **

Job Scenario ** | ** Recommendation level ** | ** Example ** |

|----------------------------|--------------|------------------------------------|

| Food processing (meat and fish cutting) | grade C~D | stainless steel wire composite gloves (non-cutting + non-slip) |

| Handling glass or installing | B to C | aramid fiber gloves |

| Automotive maintenance (Metal parts handling) | Grade C to D | HPPE fiber +PU coated gloves |

| Fire/Rescue demolition | Class E | Spectra fiber + puncture resistant design |

2. ** Take into account other performance **

- ** Anti-oil ** : Choose gloves with PU or nitrile coating.

- ** High temperature resistance ** : Aramid fiber (Kevlar) gloves can withstand high temperatures below 200℃.

- ** Sensitive touch ** : Ultra-thin stainless steel wire gloves are suitable for precision work (such as surgical instrument handling).

5, use precautions

1. how to Wear correctly?

- Make sure the gloves completely cover the wrist to avoid skin exposure.

- Check whether there is damage or open wire, timely replacement.

2. Cleaning and maintenance

- Hand washing is the main method to avoid damage to fiber structure caused by machine washing.

- Store in a dry place away from light after drying to prevent aging of materials.

3. Avoid mistakes

- Misunderstanding: "High grade gloves are absolutely safe" → Even E grade gloves can not resist continuous high pressure cutting, need to cooperate with standard operation.

- Misunderstanding ** : "Cutting gloves can replace special stab-proof gloves" → Cutting ≠ stab-proof, composite protection models need to be selected according to the risk.

6, At end

Cutting gloves are designed with high strength materials and construction to provide specific cutting protection for the hand, and their classification

(e.g. EN 388) helps users to accurately match risk scenarios. To maximize protection and reduce the risk of occupational injury,

you need to balance protection levels, flexibility and additional features (such as non-slip and oil resistance),

and follow proper use and maintenance methods.

Delivery is prompt!

By 10-year industry experts!

Diverse payment methods available!

Unbeatable cost performance!