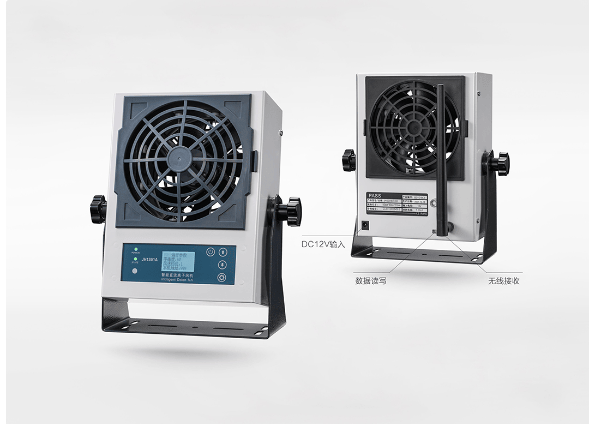

A smart networked DC esd ionizer

is a high-efficiency static elimination device that utilizes direct current (DC) ionization technology and features network connectivity for remote monitoring and control. It quickly neutralizes static electricity, preventing damage to electronic components, dust attraction, and other issues. It is widely used in electronics manufacturing, semiconductors, precision instruments, medical equipment, and cleanrooms.

✅ Smart Network Connectivity – Supports Wi-Fi/Industrial Ethernet connection, allowing remote monitoring of fan status via PC or mobile devices.

✅ESD Ionizer Technology – Independent positive and negative ion emitters provide faster static elimination and more stable ion balance.

✅ High Static Elimination Efficiency – Ideal for ESD protection of precision electronic components, with low residual voltage to prevent excessive electrostatic interference.

✅ Adjustable Airflow Speed – Multiple speed settings to meet different application requirements.

✅ Automatic Ion Balance Adjustment – Equipped with a sensor feedback system to maintain balanced ion output, preventing static buildup.

✅ Low Ozone Emission – Complies with international safety standards, ensuring long-term operation without health risks.

✅ Remote Alarm Function – Sends alerts via network in case of malfunctions, making maintenance easier.

| Feature | DC esd ionizer | AC esd ionizer |

|---|---|---|

| Ion Generation | Independent positive and negative emitters, more stable ion output | Alternating positive and negative ions, lower ion concentration |

| Static Neutralization Speed | Faster (shorter neutralization time) | Relatively slower |

| Ion Balance Control | More precise and adjustable | Auto-balancing but less controllable |

| Application Scope | High-precision electronics, cleanrooms, laboratories | General industrial applications |

| Network Connectivity | Supports remote monitoring and adjustments | Manual adjustments required |

| Ozone Emission | Lower, more environmentally friendly | Slightly higher |

📌 Semiconductor Manufacturing – Prevents damage to chips and IC components caused by static electricity.

📌 Electronics Assembly Workshops – Protects precision electronic components and improves production yield.

📌 Cleanrooms – Ensures a dust-free and static-free production environment.

📌 Precision Instrument Manufacturing – Prevents small parts from sticking or jumping due to static charges.

📌 Medical Equipment Production – Protects sensitive medical electronics from electrostatic interference.

✔ Smart networking for remote monitoring and easy maintenance.

✔ DC ionization technology for fast static elimination.

✔ Low ozone emission for a safer, more eco-friendly solution.

✔ Ideal for high-precision manufacturing environments, such as cleanrooms, semiconductor, and medical electronics industries.

An ESD Ionizer is a device designed to neutralize static electricity by generating positive and negative ions that neutralize electrostatic charges on objects or surfaces. It is commonly used in electronics manufacturing, cleanrooms, and precision industries to prevent electrostatic discharge (ESD) damage to sensitive components.

1️⃣ Ion Generation

The ionizer uses AC or DC high voltage to ionize the surrounding air, splitting neutral air molecules into positive and negative ions.

2️⃣ Ion Dispersion

A fan or compressed air blows the ions toward the target surface.

The ions disperse evenly and travel to neutralize static charges.

3️⃣ Static Neutralization

If the surface has a negative charge, it attracts positive ions from the ionizer.

If the surface has a positive charge, it attracts negative ions from the ionizer.

This process neutralizes the electrostatic charge, preventing dust attraction, product defects, and ESD damage.

🔸 Overhead Ionizing Fan – Mounted above workstations for large-area static control.

🔸 Benchtop Ionizer – Placed near workstations to protect delicate components.

🔸 Ionizing Air Gun – Handheld tool that blows ionized air to remove static from specific objects.

🔸 Ionizing Bar – Used in conveyor systems and assembly lines for wide-area neutralization.

✔ Prevents Electrostatic Discharge (ESD) – Protects sensitive electronic components from damage.

✔ Reduces Dust Accumulation – Prevents dust particles from sticking to surfaces due to static electricity.

✔ Improves Product Quality – Eliminates static-related defects in electronics and precision manufacturing.

✔ Enhances Safety – Prevents static sparks that could cause fires or explosions in flammable environments.

✅ Electronics Manufacturing – Protects circuit boards, semiconductors, and IC chips.

✅ Cleanrooms & Laboratories – Maintains a controlled environment free from static contamination.

✅ Plastic & Printing Industries – Prevents static cling and uneven printing.

✅ Medical Equipment Production – Ensures static-free assembly of sensitive devices.

✅ Industrial Assembly Lines – Eliminates static attraction of dust and debris.

An ESD Ionizer works by generating and distributing positive and negative ions, which neutralize static charges on surfaces and objects. It is essential for preventing ESD damage, reducing dust buildup, and improving product quality in industries where static electricity can be a problem.

Would you like recommendations on specific ESD ionizer models? 😊

Delivery is prompt!

By 10-year industry experts!

Diverse payment methods available!

Unbeatable cost performance!