What is a Grounding Wristband?

A Grounding Wristband is a personal Electrostatic Discharge (ESD) control device worn on the wrist to safely discharge static electricity from the human body to ground. It prevents the buildup and sudden release of static charges that could damage electronic components, semiconductors, or ignite flammable substances in sensitive environments.

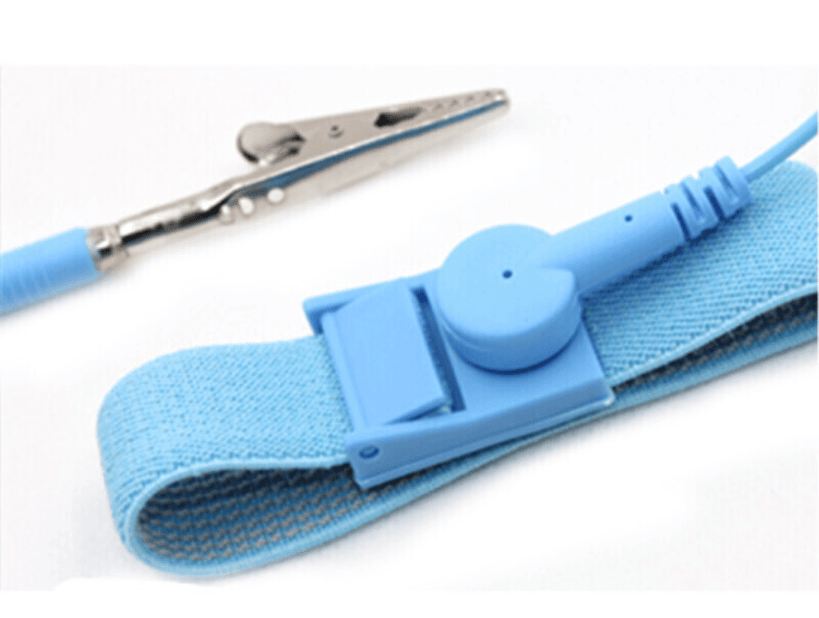

Components of a Grounding Wristband

A typical grounding wristband includes the following parts:

| Component | Function |

|---|---|

| Wrist Strap | Worn on the wrist to ensure contact with the skin. Made of conductive threads (often elastic) or metal links. |

| Coiled Grounding Cord | A flexible cord connecting the strap to ground, typically includes a 1 MΩ resistor for safety. |

| Ground Clip or Plug | Connects to a ground point such as a mat, common ground point, or electrical ground socket. |

| Safety Resistor | Usually 1 megaohm (10⁶ Ω) built-in to prevent accidental electrical shock while allowing static flow. |

Types of Grounding Wristbands

| Type | Description |

|---|---|

| Wired Wristband | Most common; connects to a ground via a coiled cord. Offers continuous grounding. |

| Wireless (Cordless) | Uses ionization or field-based grounding without physical wires. Less common, usually more expensive. |

| Metal Band | Durable, commonly used in high-end or cleanroom environments. |

| Elastic Fabric Band | Comfortable, often adjustable, and commonly used in manufacturing and repair areas. |

Working Principle

The grounding wristband works by creating a path of least resistance from the human body to ground:

The strap contacts the skin, allowing static from the body to enter the conductive material.

The grounding cord channels the static electricity through a resistor (usually 1 MΩ).

The cord terminates in a ground point (e.g., metal surface, grounded plug, or ESD mat).

The static electricity is safely dissipated to Earth, preventing damage or ignition.

Key Specifications

| Specification | Typical Value |

|---|---|

| Resistance to Ground | 10⁶–10⁷ ohms |

| Resistor in Cord | 1 MΩ (±10%) |

| Cord Length | 1.8–2.5 meters |

| Strap Material | Nylon, polyester with conductive fibers or stainless steel |

| Ground Connection | Alligator clip, banana plug, or 10 mm snap |

| Color Options | Blue, black, red (common industry standards) |

Applications

Grounding wristbands are essential in:

Electronics manufacturing

Semiconductor fabrication

PCB assembly and testing

Repair centers (laptops, phones, etc.)

Aerospace and defense electronics

Cleanrooms

Flammable/explosive environments

How to Use a Grounding Wristband

Wear the strap snugly on your wrist (skin contact required).

Connect the cord to the wristband snap.

Attach the cord’s other end to a grounded point, such as:

ESD mat with proper grounding

Grounded equipment

Building ground (via a 3-prong plug or ESD socket)

Verify resistance and continuity using a wrist strap tester before use.

Remain connected as long as you are handling ESD-sensitive devices.

Maintenance Tips

Regularly test for continuity with a wrist strap tester.

Clean the strap (especially fabric types) to remove skin oils or dirt that reduce conductivity.

Inspect the cord and plug for wear or damage.

Replace the strap if resistance values are out of specification.

Advantages

Cost-effective, reliable ESD protection.

Simple to use.

Reduces risk of latent damage in sensitive electronics.

Portable and reusable.

Helps companies comply with ANSI/ESD S20.20, IEC 61340-5-1, and other ESD control standards.

If you need help choosing the right wristband (e.g., for cleanroom, heavy use, or fieldwork), feel free to contact with us!