How Does an ESD Wrist Strap Protect Products in the Workplace?

Principle of Wired ESD Wrist Strap

The wired ESD wrist strap works by safely discharging static electricity from the human body to the ground through the wristband and grounding wire.

🔹 How It Works:

1️⃣ The wristband makes direct contact with the skin, ensuring effective conductivity.

2️⃣ The grounding wire connects the wrist strap to an ESD-safe grounding point.

3️⃣ This setup allows static charges to safely dissipate to the ground, preventing damage to sensitive electronic components.

🔹 Key Features:

✔ Instant Discharge – Removes static electricity within 0.1 seconds.

✔ Reliable Protection – The most fundamental and widely used ESD protection tool.

✔ Simple & Effective – Essential for electronics assembly, repair, and static-sensitive environments.

Would you like a comparison between wired vs. wireless ESD wrist straps? 😊

What is an ESD Wrist Strap?

An ESD wrist strap is a specialized device designed to prevent electrostatic discharge (ESD) from damaging sensitive electronic components. It is commonly used in electronics manufacturing, repair, and cleanroom environments.

How It Works:

1️⃣ The wristband makes direct contact with the skin, allowing static charges from the human body to be transferred.

2️⃣ A grounding cord connects the wrist strap to an ESD-safe ground point, ensuring a continuous discharge of static electricity.

3️⃣ This prevents the buildup of static charges, which could otherwise damage sensitive electronic components.

Types of ESD Wrist Straps:

✔ Wired ESD Wrist Strap – Directly connects to a ground point for reliable discharge.

✔ Wireless (Cordless) ESD Wrist Strap – Uses special materials to dissipate static but is generally less effective than wired versions.

Why Use an ESD Wrist Strap?

✅ Protects Electronics – Prevents static damage to circuit boards, semiconductors, and microchips.

✅ Essential for Workplaces – Required in factories, labs, and cleanrooms handling static-sensitive devices.

✅ Simple & Cost-Effective – An easy-to-use, affordable solution for ESD control.

Would you like recommendations for choosing the best ESD wrist strap for your needs? 😊

An ESD wrist strap is a crucial tool in Electrostatic Discharge (ESD) protection, primarily used in electronics manufacturing, assembly, and repair. It helps prevent static electricity buildup on workers, which could otherwise damage sensitive electronic components.

🔹 Key Components:

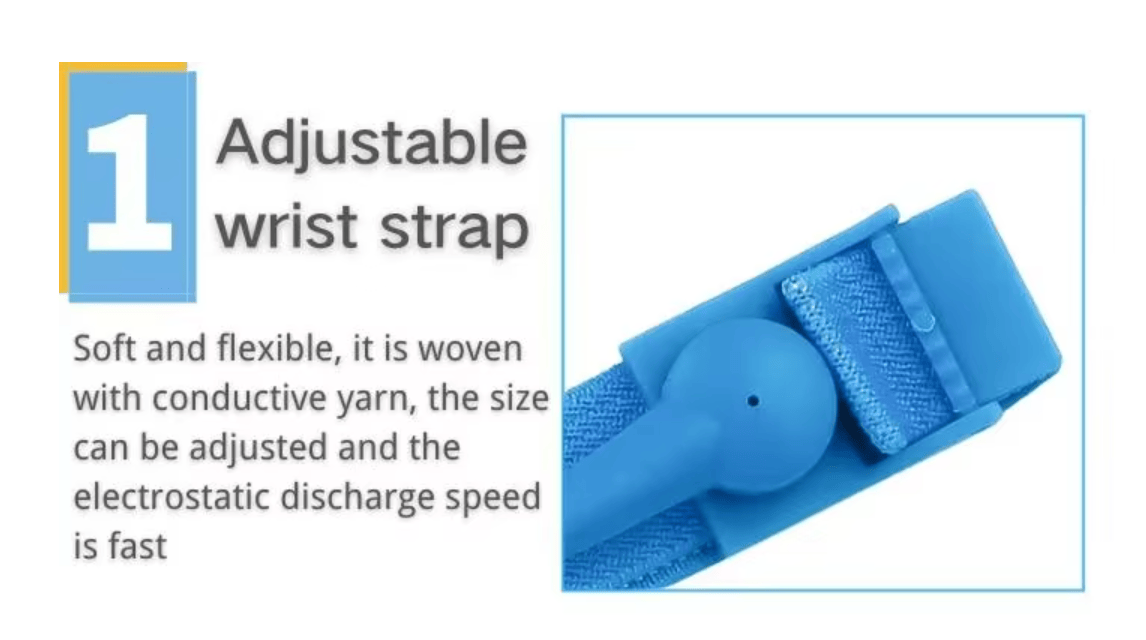

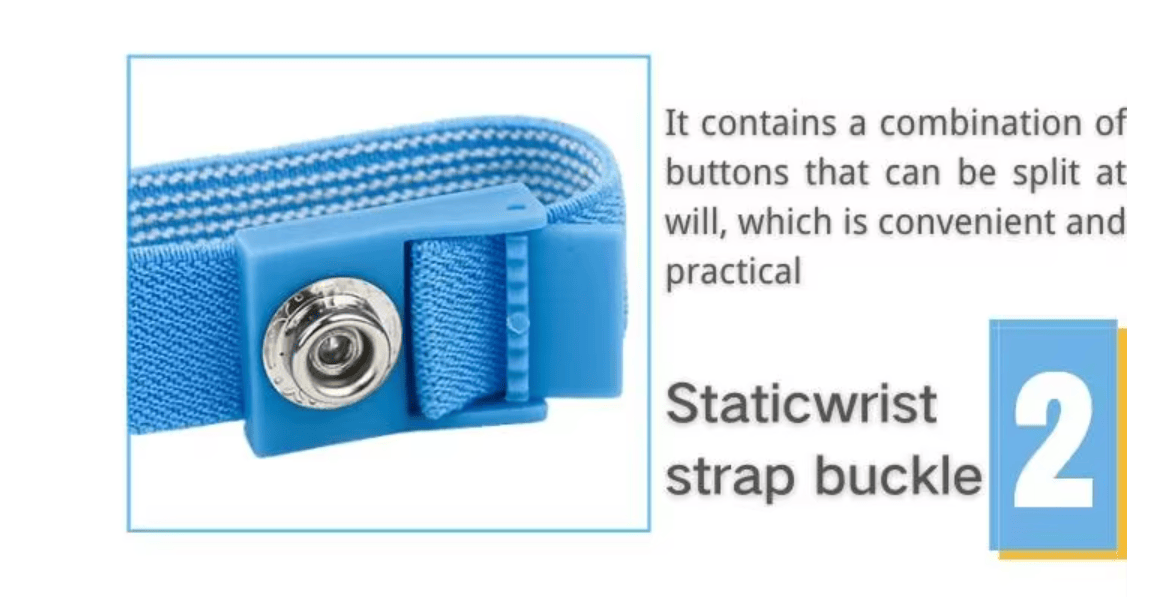

✔ Conductive Band – Worn around the wrist, made of conductive materials (carbon, metal fibers).

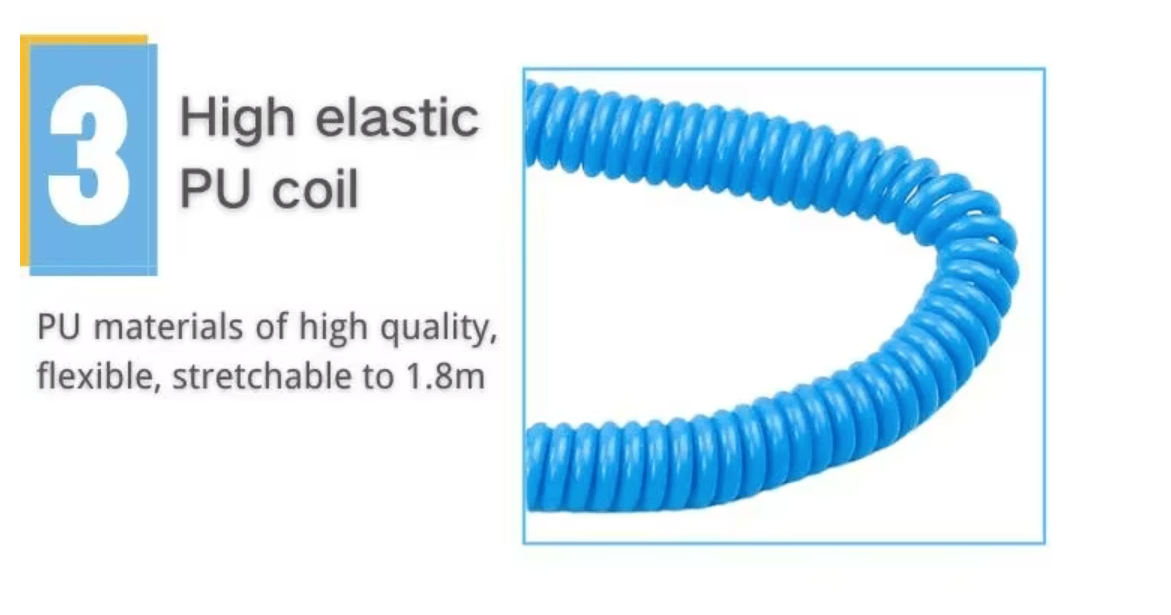

✔ Coil Cord & Resistor – The coiled grounding cord connects to an earth ground (e.g., grounded workstation, common ground point) and contains a 1MΩ resistor for safety.

✔ Grounding Point – Clips or plugs into an ESD-safe ground, ensuring proper dissipation of static charges.

🔹 Workplace Applications:

✅ Electronics Assembly & Repair – Protects circuit boards, microprocessors, and chips.

✅ Semiconductor Manufacturing – Prevents damage to highly sensitive semiconductor wafers.

✅ Cleanrooms & ESD-Safe Workstations – Used in environments where even a small static charge can ruin components.

🔹 Best Practices for Using ESD Wrist Straps:

✔ Always test the strap before use with an ESD wrist strap tester.

✔ Ensure it’s properly connected to an ESD-safe grounding point.

✔ Wear it snugly on bare skin for proper conductivity.

✔ Regularly inspect the cord and resistor to ensure functionality.

🔹 Why It’s Essential:

⚡ Without an ESD wrist strap, even a tiny static discharge (as low as 100V) can damage sensitive electronics, leading to failures, costly repairs, or product defects.

ESD wired wrist strap is the most basic of anti-static equipment, is also the most widely used in the production line is necessary article, not only on the construction and operation is very convenient, the price is also the most economical and practical, its reason is through the wrist strap and ground wire, to human body electrostatic discharge to the earth, so use wristbands necessary really contact with the skin, also need direct grounding earth wire, and ensure the grounding line unimpeded to maximum effect. Features: 1.Used to prevent electrostatic discharge (ESD) by safely grounding a person working with electronic equipments or at an electronic assembly facility. 2.They are usually used in conjunction with an ESD mat on the workbench, or a special static-dissipating plastic laminate on the workbench surface. Application: Product line, CMOS chip, microprocessor, semiconductor, dish drivers, LCD screen product, circuit product line, precision instrument, optics part and so on.