What are the new applications of ESD gloves?

ESD Gloves: The Invisible Guardian of Modern Industry

In a dust-free semiconductor packaging workshop, the moment engineer Wang Min puts on a pair of black ESD gloves, the electrostatic detection value on the display instantly drops from the dangerous red zone to the safe green zone. This seemingly small action protects millions of dollars' worth of precision electronic components from electrostatic damage. In the 21st century’s high-tech manufacturing industry, ESD gloves have evolved from ordinary labor protection tools into indispensable guardians of precision manufacturing, with a level of technological sophistication and application value far beyond common perception.

I. The Inner Mechanics of ESD Technology

The core secret of ESD gloves lies in the precision design of material engineering. The composite weaving of carbon fibers and metal fibers forms a three-dimensional conductive network, while the gradient distribution of conductive rubber creates dynamic charge pathways. These innovative materials stabilize the surface resistance in the optimal range of 10⁴-10⁹Ω. Unlike ordinary insulating materials, these conductive media enable directed charge migration through quantum tunneling effects, forming an electronic expressway at the microscopic level.

A dual-layer protection mechanism—a combination of electrostatic neutralization and electrostatic shielding—further enhances effectiveness. The outer layer of the gloves continuously releases static charge through the corona discharge principle, while the inner conductive mesh creates a Faraday cage effect, directing residual charges safely to the grounding system. This hybrid protection model reduces electrostatic dissipation time to 0.1 seconds and achieves an efficiency of 99.99%.

The latest smart gloves integrate nanotechnology sensor arrays to monitor contact voltage and leakage current in real time. If an abnormal discharge is detected, the built-in piezoelectric material triggers haptic feedback alerts, creating an intelligent human-machine collaborative defense system. This technological breakthrough upgrades static protection from passive defense to proactive warning systems.

II. The Invisible Shield in Industrial Applications

In microelectronics manufacturing, 0.3-micron-wide chip circuits are extremely sensitive to electrostatic damage. A semiconductor company that introduced graphene-enhanced gloves saw its product defect rate drop from 5 in 10,000 to just 1 in 1,000,000.

In biotechnology laboratories, ESD gloves prevent protein samples from static-induced losses, improving gene sequencing data integrity by 40%.

In medical device assembly lines, ESD gloves ensure implantable medical equipment remains unaffected by electrostatic discharge (ESD).

In aerospace engineering, specially designed gloves maintain stable conductivity even in a vacuum, providing ultimate protection for satellite components.

These cross-industry applications have given rise to customized solutions, where glove specifications are tailored to meet the unique electrostatic protection needs of different sectors.

A leading automotive electronics supplier provides a compelling case study: after implementing a multi-level static protection system, the monthly ESD incidents in their factory dropped from 12 to zero, and product failure rates within the warranty period decreased by 65%. This demonstrates that scientific static protection strategies yield significant economic benefits, with a potential return on investment exceeding 300%.

III. The Science Behind Selection and Usage

Selecting ESD gloves requires a three-dimensional evaluation model:

Conductive performance should meet IEC 61340-5-1 standards.

Mechanical strength should pass the EN 388 abrasion test.

Chemical resistance should match the specific working environment.

Medical-grade gloves must be FDA-certified, while cleanroom gloves must pass ISO 14644 particle emission tests.

For proper use and maintenance, the "Three-Degree Principle" applies:

Maintain humidity levels between 40%-60% RH for optimal static dissipation.

Ensure operating temperatures do not exceed the material’s glass transition point.

Apply a contact pressure of 5-20 kPa to maintain the best conductivity.

Cleaning should be done with ionized cleaning agents instead of alcohol-based solvents, which could degrade conductive coatings.

IV. Future Trends in ESD Protection

The evolution of ESD technology is following three major trends:

Self-healing conductive materials extend the lifespan of gloves by 3 times.

Biodegradable bio-based materials address environmental concerns.

Brain-machine interface gloves are being developed to integrate human-computer interactions.

In a nano-robot assembly workshop, a new generation of quantum-dot ESD gloves is undergoing final testing. These gloves not only eliminate static electricity but also regulate surface potential to assist in micro-assembly operations.

ESD protection technology has surpassed its traditional role and is now becoming an enabling force in advanced manufacturing. When we observe the movement of electrons on these gloves, we are witnessing not just the dissipation of static charges, but humanity’s mastery over the microscopic world.

carbon fiber carbon fiber

What Are ESD Gloves?

ESD (Electrostatic Discharge) gloves are specialized gloves designed to prevent the buildup and discharge of static electricity. They are widely used in industries where static-sensitive electronic components or equipment must be protected from electrostatic damage.

PU coatings copper fiber

How Do ESD Gloves Work?

ESD gloves are made from materials such as carbon fiber, copper fiber, or conductive coatings, which create a controlled path for static electricity to dissipate safely. This prevents accidental electrostatic discharge that could damage delicate electronic components.

Applications of ESD Gloves

ESD gloves are essential in:

Electronics manufacturing (assembling circuit boards, semiconductors, and microchips)

Aerospace and automotive industries (handling sensitive sensors and electrical components)

Medical device manufacturing (protecting delicate instruments from static damage)

Cleanrooms (preventing contamination and static interference)

Types of ESD Gloves

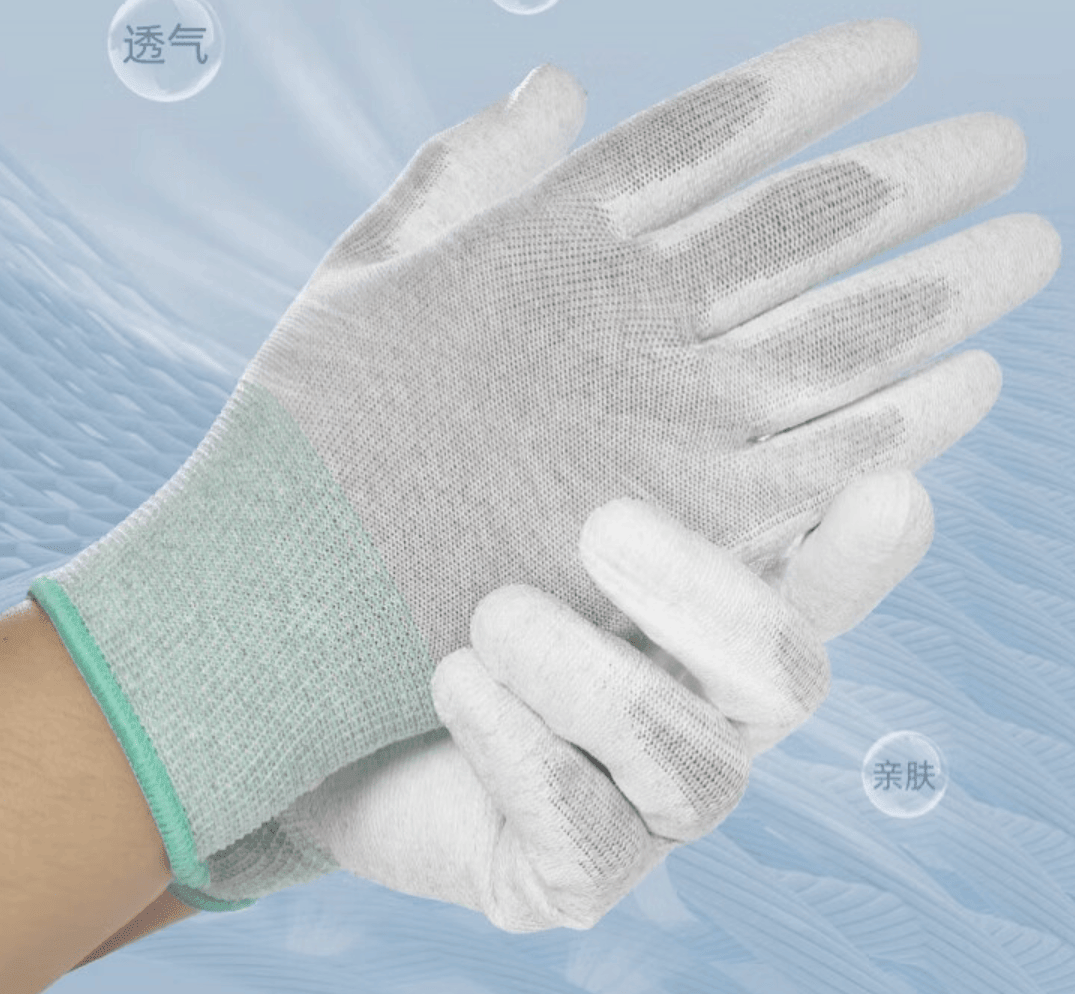

Fabric ESD Gloves – Made with polyester or nylon infused with conductive fibers, offering flexibility and breathability.

Coated ESD Gloves – Feature PU (polyurethane) or nitrile coatings for better grip and durability.

Full Conductive Gloves – Provide maximum protection by ensuring conductivity throughout the glove.

Touchscreen-Compatible ESD Gloves – Allow users to operate touchscreen devices without removing gloves.

Why Use ESD Gloves?

Using ESD gloves ensures that workers do not transfer static charges to sensitive components, preventing costly damage and ensuring compliance with ESD safety standards (IEC 61340-5-1, ANSI/ESD S20.20).

ESD Factorys' Gloves Advantage :

COMFORTABLE

Lightweight, flexible, and dexterous, excellent breathability keeps hands cooler, dryer and more productive. They can snug fit to all fingers for men and women, providing accuracy and comfort during the general duty outdoor work due to ultra-thin feature.

SUPERIOR GRIP

Coated with grippy Polyurethane coating, provide extra grip and the strong abrasion protection across the palm and fingers. when grabbing construction materials and tools for outside work. PU coating maintains the grip in dry, wet, and light oily conditions, make the men, like the workers able to hold the objects firmly.

TOUCHSCREEN COMPATIBLE

Can add touchscreen-friendly function. In this way, men and women no need to take off the work gloves to slide to unlock the screen and answer the phone, which is extreme convenient for gardening yard work, handling or moving boxes and other occasions need to give consideration to operating the touchscreen equipment and duty work.MULTI- PURPOSE

Ideal for general light duty construction work, mechanic works, plumbing, gardening, warehouse package handling etc. Grip working gloves act as a great helper for men and women, adult and youth who need working gloves to protect their hands in work or life.DURABLE

Designed for both men and ladies. People could choose the sizes according to the width and length of their own palms. The gloves in differents sizes respectively correspond to the various colors of the overlook stitches, obviously to figure out yours from others. Qualified for thousands of the machine wash and abrasion cycle tests, the strengthened PU coating gloves has significantly ultra-long-life span than others.

Comply with the EU REACH Regulation, CE certified with EN388:2016 4131X