ESD mat (Electrostatic Discharge mat) is a specialized surface material used to prevent the accumulation and discharge of static electricity in sensitive work areas, especially where electronic components or flammable substances are present.

It works by providing a controlled low-resistance path to ground, allowing static charges to dissipate safely and gradually.

Electrostatic discharges as small as 100 volts (often imperceptible to humans) can damage electronic components, such as microchips, transistors, and circuit boards. ESD mats help eliminate this risk by:

Neutralizing electrostatic build-up on personnel and objects.

Providing a grounded surface for handling static-sensitive devices.

Reducing downtime and defects in manufacturing environments.

A dissipative or conductive surface absorbs static charges from any objects or personnel that come into contact with it.

The static electricity is channeled through the mat’s layers to a grounding point (usually via a grounding wire).

The charge is safely discharged to the earth, preventing damage to nearby equipment.

ESD mats must be connected to ground and often used in conjunction with wrist straps, heel straps, or grounding cords for full-body protection.

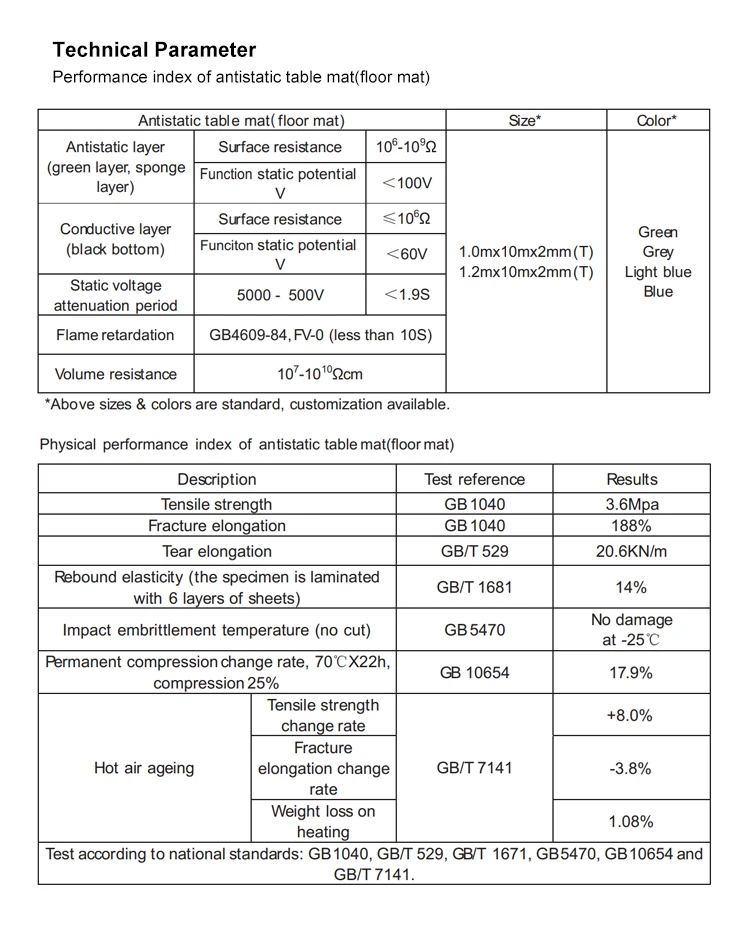

| Material | Role | Properties |

|---|---|---|

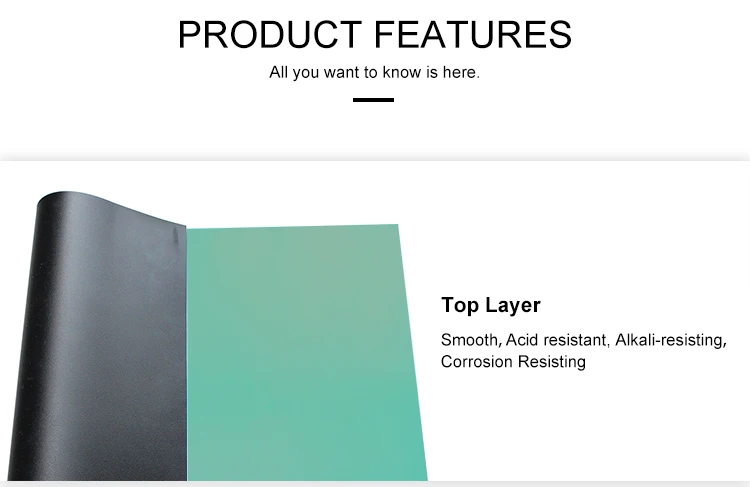

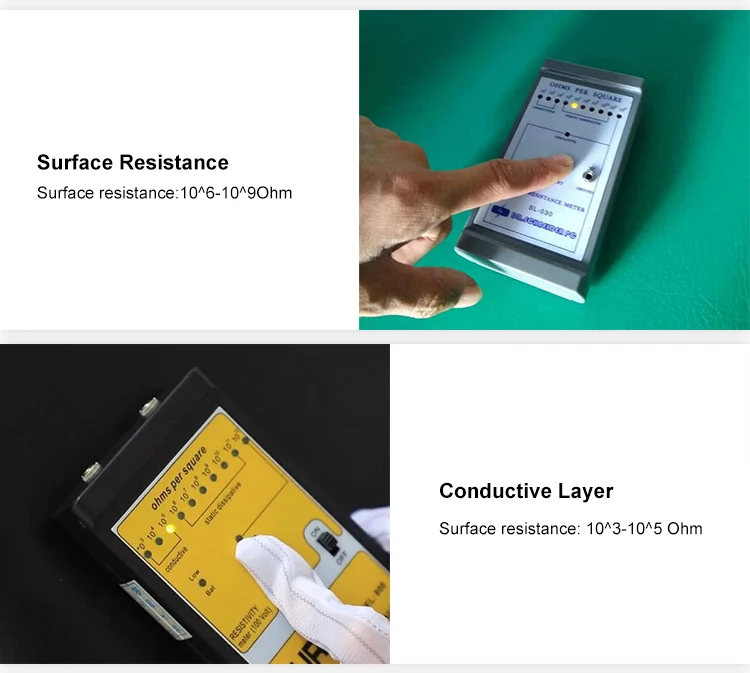

| Conductive Rubber | Base layer | Rapid discharge of electricity |

| Dissipative Vinyl or Rubber | Top layer | Slower, controlled discharge |

| Foam/Insulating Layer | Middle (optional) | Comfort and cushioning |

Most mats are two-layer (dissipative + conductive) or three-layer (with foam core) constructions.

| Type | Description | Usage |

|---|---|---|

| Table/Bench Mats | Flat, placed on workbenches | Common in electronics assembly |

| Floor Mats | Placed on floors or under workstations | Works with heel straps for grounding personnel |

| Interlocking Tile Mats | Modular and scalable | Large production areas |

| Cleanroom ESD Mats | Low particulate emission | Semiconductor & pharmaceutical labs |

| Roll-Up Mats | Portable and flexible | Mobile service and field repair |

| Property | Value |

|---|---|

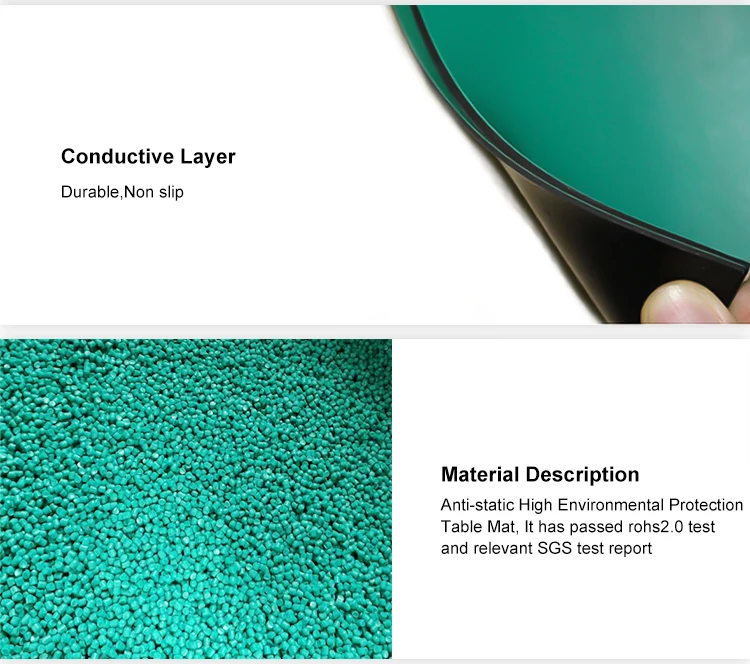

| Surface Resistance | 1×10⁶ to 1×10⁹ ohms |

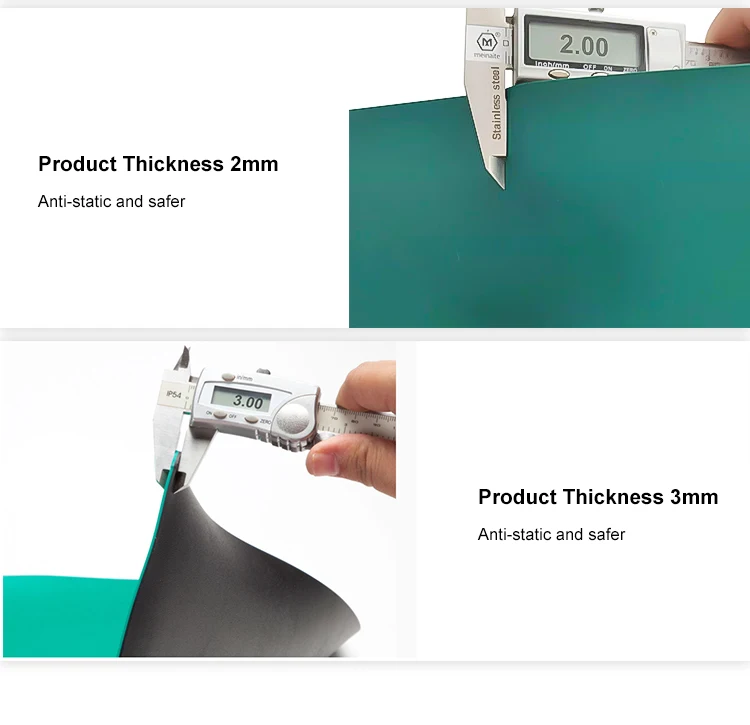

| Thickness | 2–4 mm standard |

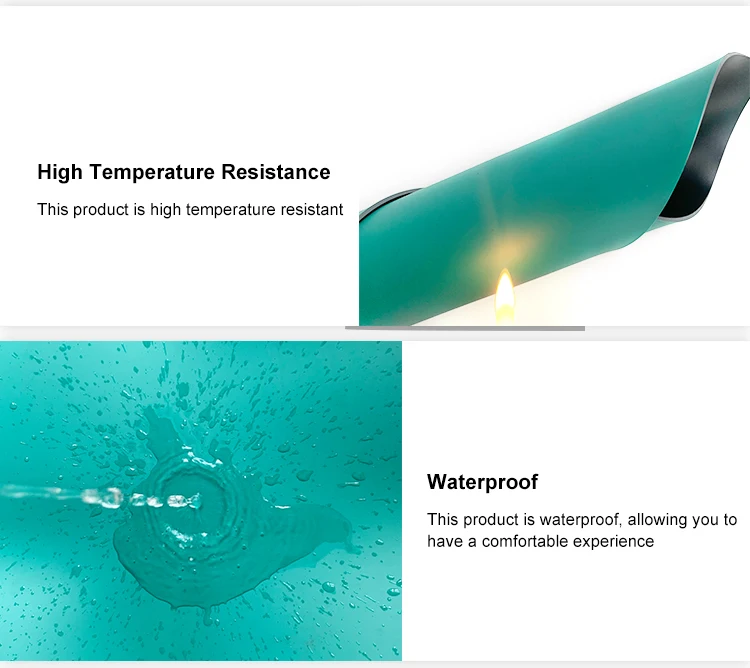

| Temperature Resistance | Up to 120°C (varies) |

| Chemical Resistance | High (rubber types), Moderate (vinyl) |

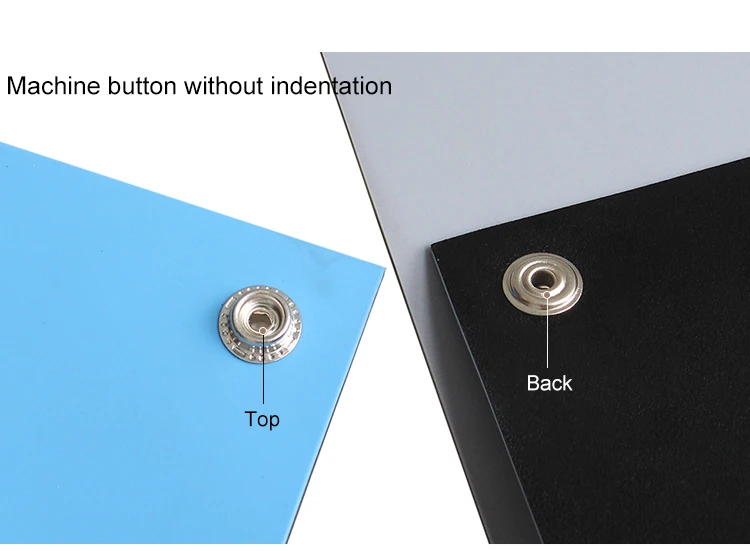

| Grounding Snap | 1 Megohm resistor included for safety |

| Standards | ANSI/ESD S20.20, IEC 61340-5-1 |

Electronics manufacturing: PCB handling, soldering stations

Repair and assembly: Phone/computer service centers

Cleanrooms: Semiconductor production, biotech labs

Industrial control systems: To protect I/O and sensor circuits

Explosive environments: Prevent spark ignition (anti-static focus)

Place the mat on a flat surface (table or floor).

Attach the grounding cord to the snap connector (typically pre-installed).

Connect the cord to ground (grounding plug, ESD socket, or ESD ground point).

Test grounding continuity using an ESD tester.

Use in conjunction with:

Wrist straps

ESD footwear or heel straps

Ionizers (optional in dry environments)

Clean regularly with ESD-safe cleaner (avoid alcohol or ammonia).

Inspect for wear or damage in top layer and grounding snap.

Test regularly (recommended: monthly) with a surface resistance meter.

Replace if resistance is out of spec or if grounding fails.

| Feature | ESD Mat | Anti-Static Mat |

|---|---|---|

| Purpose | Grounding static-sensitive components | Reduces static generation only |

| Grounding | Yes (required) | Optional |

| Surface Resistance | 10⁶–10⁹ Ω | 10⁹–10¹² Ω |

| Applications | Electronics, cleanroom | Packaging, carpet, general areas |

Reduce static damage in sensitive environments

Improve yield and reliability in electronics manufacturing

Easy to install and use

Cost-effective ESD protection solution

Long-lasting and durable (especially rubber types)

| Parameter | Description |

|---|---|

| Function | Discharge static safely to ground |

| Material | Dissipative vinyl or rubber over conductive base |

| Resistance | Typically 10⁶–10⁹ ohms |

| Installation | Needs grounding connection |

| Use Cases | Electronics labs, cleanrooms, PCB assembly |

| Standards | ANSI/ESD S20.20, IEC 61340-5-1 |

Would you like a visual diagram showing ESD mat layers and grounding setup?

Delivery is prompt!

By 10-year industry experts!

Diverse payment methods available!

Unbeatable cost performance!